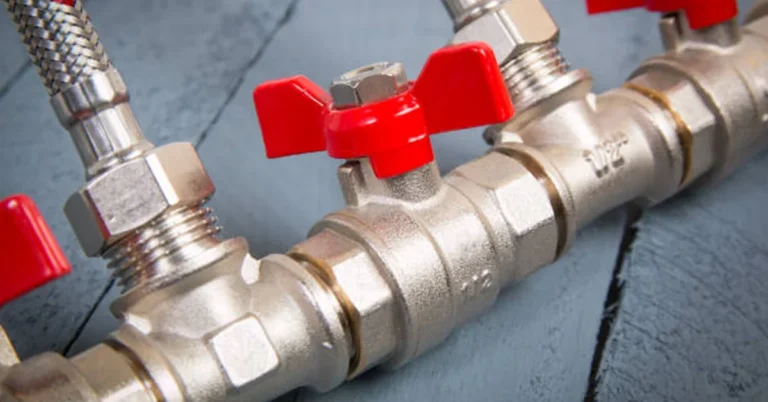

Ball valves are critical components in many industries due to their ability to regulate and control the flow of liquids, gases, and slurries efficiently. With their simple design and reliable performance, ball valves are commonly used in applications ranging from water treatment plants to petrochemical facilities. This article explores the importance of high-quality ball valve solutions, the key factors that ensure their reliable performance, and how to select the right valve for your needs.

TRENDING

What Are Okuninushi Patrons In Japanese Mythology?

What Is A Ball Valve?

A ball valve is a type of quarter-turn valve that uses a spherical ball with a hole through its center (the “ball”) to control the flow of media through a pipeline. When the valve handle is turned, the ball rotates to either allow or block the flow. This straightforward design makes ball valves suitable for on/off control applications, where a tight shutoff is required.

The key advantage of ball valves is their ease of use and reliability. They can be used in a wide range of industries, including oil and gas, water treatment, food and beverage, HVAC, and chemical processing. When properly designed and manufactured, ball valves provide excellent performance and a long lifespan, minimizing the risk of leaks or other failures.

The Importance Of High-Quality Ball Valves

Ball valves are often subjected to demanding conditions such as high-pressure environments, extreme temperatures, or exposure to aggressive chemicals. Therefore, selecting a high-quality ball valve is essential for ensuring reliable performance. High-quality ball valves are constructed using durable materials and advanced manufacturing techniques to ensure they can withstand these challenging conditions. The benefits of investing in top-tier ball valve solutions include:

- Extended Service Life: High-quality ball valves are designed to last for many years, even in harsh environments. This reduces maintenance costs and ensures the smooth operation of your systems.

- Reliable Performance: A premium ball valve provides consistent and reliable flow control, minimizing the risk of leaks and system failure.

- Tight Shutoff: High-quality valves offer a more effective seal, preventing leakage of fluids or gases, which is critical in applications where safety and efficiency are paramount.

- Reduced Downtime: Because of their long lifespan and reliability, high-quality ball valves reduce the need for frequent replacements or repairs, ensuring the continuous operation of your systems.

- Energy Efficiency: High-performance valves help optimize the flow of media, reducing energy waste and improving the overall efficiency of the system.

Key Factors To Consider When Choosing Ball Valves

When selecting ball valves for a particular application, several key factors must be considered to ensure reliable performance. These include:

Material Selection

The material used to manufacture a ball valve plays a crucial role in its performance. Common materials for ball valves include stainless steel, brass, carbon steel, and plastics like PVC. The choice of material will depend on the type of media the valve will control (e.g., water, oil, chemicals), the operating temperature, and the pressure requirements.

- Stainless Steel: Ideal for corrosive and high-temperature applications.

- Brass: Common in water and gas systems, offering good corrosion resistance at lower costs.

- Carbon Steel: Suitable for high-pressure applications and handling oil and gas.

- PVC/Plastic: Used in low-pressure systems and non-corrosive environments.

Size and Pressure Rating

Ball valves come in various sizes, typically ranging from 1/8 inch to several inches in diameter. The size of the valve should be chosen based on the diameter of the pipe and the flow rate required for the system. Additionally, ball valves are rated for different pressure levels, and choosing the correct pressure rating ensures the valve can handle the operating conditions without failing.

End Connections

Ball valves are available with various end connections, including flanged, threaded, and welded types. The right connection type will depend on the piping system in use. For example, flanged connections are ideal for high-pressure systems, while threaded connections are more suitable for smaller pipes or residential applications.

Seal Type

The seal is one of the most important components of a ball valve, as it ensures the valve provides a tight shutoff. Common seal materials include PTFE (Polytetrafluoroethylene), graphite, and elastomers, each offering specific benefits in terms of temperature resistance, chemical compatibility, and sealing performance. High-quality seals ensure minimal leakage and better performance over time.

Operation Type

Ball valves can be operated manually (with a handle or lever) or automatically (with an actuator). For larger systems or processes that require frequent adjustments, automated ball valves are often preferred. Electric, pneumatic, or hydraulic actuators can be used to control the valve, improving efficiency and reducing the risk of human error.

Design Features

Some ball valves come with additional design features to enhance performance and longevity. These may include:

- Blow-out Proof Stem: Prevents the stem from being ejected under high pressure.

- Self-Adjusting Stem Packing: Helps maintain a tight seal over time.

- Multi-Port Valves: Allow for more complex flow control, such as diverting or mixing flows.

Applications Of Ball Valves

Ball valves are used across a variety of industries. Some of the most common applications include:

Oil and Gas Industry

In the oil and gas sector, ball valves are used to control the flow of oil, gas, and other fluids under high pressure and extreme conditions. Ball valves are particularly useful for on/off control and can be found in upstream, midstream, and downstream applications.

Water Treatment Plants

Ball valves are essential in water and wastewater treatment plants, where they regulate the flow of water through various treatment processes. They ensure the flow is efficiently managed, preventing overflows or contamination.

Chemical Processing

The chemical industry relies on ball valves to control the flow of corrosive or hazardous materials. Ball valves made from materials like stainless steel or plastic are highly resistant to chemical attack, ensuring safety and reliability in harsh conditions.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, ball valves control the flow of water or refrigerants through pipes. Their ability to provide a tight shutoff makes them ideal for regulating system pressure and temperature.

Food and Beverage Industry

In food processing plants, ball valves are used to control the flow of ingredients, water, and other liquids. Their smooth internal design helps minimize the buildup of bacteria and makes them easier to clean, ensuring compliance with hygiene standards.

Maintenance Tips For Ball Valves

To ensure the reliable performance of ball valves, regular maintenance is essential. Here are some tips for maintaining ball valves:

- Check for Leaks: Regularly inspect the valve for leaks around the stem and body. If leaks are detected, replace the seals or gaskets.

- Lubricate the Valve: Apply appropriate lubricants to the stem and moving parts to reduce friction and ensure smooth operation.

- Exercise the Valve: Periodically operate the valve to prevent the internal components from seizing up or becoming clogged.

- Monitor for Wear and Tear: Over time, the ball valve may show signs of wear. Check for scratches, dents, or signs of corrosion that could affect performance.

ConclusionDiscover the reliability and precision of ball valves for seamless fluid control in various industries. Durable, efficient, and easy to maintain.

High-quality ball valve solutions are essential for reliable performance in numerous industries. By selecting the right materials, sizes, and features, you can ensure that your ball valve performs optimally in even the most demanding conditions. Investing in durable, well-designed ball valves not only improves system efficiency but also minimizes downtime and reduces maintenance costs. With proper care and maintenance, a high-quality ball valve can provide years of dependable service, contributing to the overall success of your operations.

ALSO READ: Unlock Wealth With Money 6X REIT Holdings: Expert Tips

FAQs

What is a ball valve?

A ball valve is a type of valve that controls the flow of liquids or gases using a rotating ball with a hole through it. It is widely used for on/off control and is known for its simple design and reliable shutoff capability.

What materials are used to make ball valves?

Ball valves are typically made from materials such as stainless steel, brass, carbon steel, and plastics like PVC. The choice of material depends on factors like the type of fluid, pressure, and temperature conditions.

How does a ball valve work?

A ball valve works by rotating a ball with a hole in its center. When the valve handle is turned, the ball rotates to either allow or block the flow of fluid through the valve, providing on/off control.

Can ball valves be automated?

Yes, ball valves can be automated using electric, pneumatic, or hydraulic actuators. Automated ball valves are ideal for systems that require frequent adjustments or where manual operation is impractical.

What is the difference between a ball valve and a gate valve?

The main difference between a ball valve and a gate valve is that a ball valve uses a rotating ball to control flow, while a gate valve uses a sliding gate to open or close the flow path. Ball valves provide faster, more reliable shutoff, while gate valves are typically used for larger flow capacities.